CMP PLANETARY MIXER

CMP PLANETARY MIXER

Description

Product Introduction

Compact Construction, steady driving, original mode, excellence in performance and long operating life. With low investment and operational costs, easy to install and maintain with no leakage problems and leading products

Enterprise qualifications/Patent certificates: IS0900

Planetary Mixer Configuration

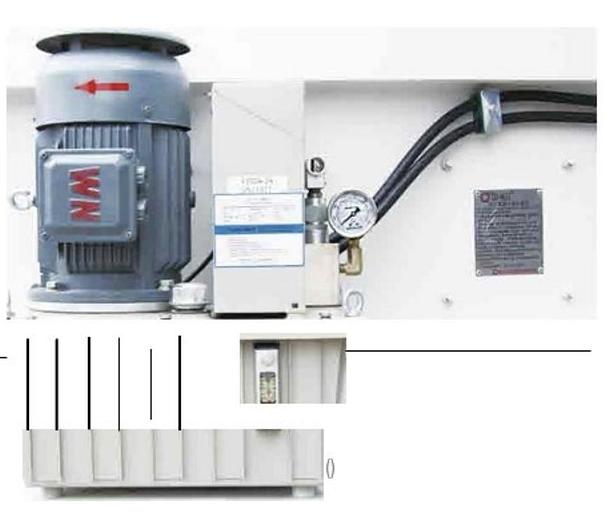

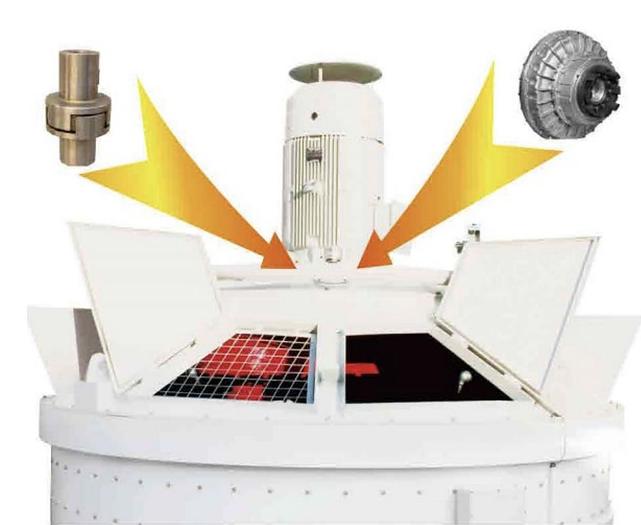

1.Gearing System: The driving system consists of motor and hardened surface gear which is specialized designed by CONELE (patented). Flexible coupling and hydraulic coupling (option) connects motor and gearbox. The gearbox is designed by CO-NELE (completely Independent Intellectual property rights owned) absorbing European advanced technology. The improved model has lower noise, longer torque and is more durable. Even in strict production conditions, the gearbox can distribute power effectively and evenly to each mix end device, ensuring normal operation, high stability, and low maintenance.

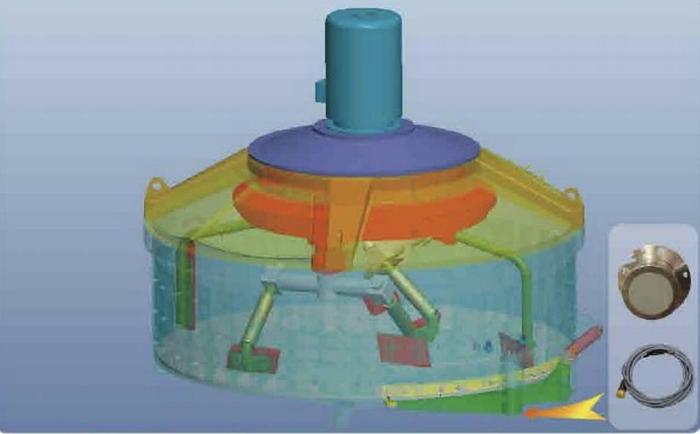

2.Motion Track: The revolution and rotation speed of the blades have been extensively studied and tested to give the mixer a high output without causing the segregation of materials with different grain size and weight. The movement of the material inside the trough is smooth and continuous. As shown in the picture, the blades track covers the whole bottom of the mixing bowl after a cycle.

3.Observing Port. There is an observing port on the maintaining door. You can observe the mixing situation without cutting off power.

4 Mixing Device. Compulsory mixing Is realised by composite movements of extruding and overturning, driven by rotating planets and blades. Mixing blades are designed in parallelogram structure(patented), which can be turned 180° for reuse to increase service life. Specialised discharge scraper has been designed according to discharge speed to increase productivity.

5.Discharging Device. According to the different demands of customers, the discharging door can be opened by hydraulic, pneumatic or by hand. The number of discharging doors is three at most. And there Is special sealing device on the discharging door to ensure the sealing reliable.

6.The Hydraulic Power Unit. A specially designed hydraulic power unit is used to provide powerfor more than one discharging gate. On emergency, these discharging gates can be opened by hand.

7.Maintenance Door and Security Device. To Improve the security of using the product, reliable high-sensitive security switches are used in the maintenance door to make the maintenance work safe and convenient.

8.Water Device. Overhead structure ls used to water (patent products). It solves the problem of residual additives and water in the pipes. Avoid customer loss in formula changing. The nozzle Which adopts spiral solid cone nozzle, has a fine uniform atomisation effect, large covering area andmake the material more uniform when mixing.

9.Experimental Test Center. We have a testing center for all kinds of material to meet the customer’s different material types for mixing.

Planetary fly-cutter mixer configuration

Mixing blades are designed in parallelogram structure(planted), which can be turned 180° for

reuse to increase service life. Specialised discharge scrapers have been designed according to

discharge speed, to Increase productivity.

1 Mixing Device. Mixing blades are designed in parallelogram structure(planted), which can be turned 180° for reuse to increase service life. Specialised discharge scrapers have been designed according to discharge speed, to Increase productivity.

2 Motion Track

Control System

We provide two modes of control system. The first mode consists of an industrial computer, weighers, control cabinet and high voltage cabinet. The second mode Is made up of PLC, touch screen, weighers, and control cabinet. Both modes adopt man-machine interface, menu options, fully automatic control of material ratio. Multiple displays of different working process makes it easy to monitor and manage production. Easy operation owes to the beautiful outline design and humanized control method. All electrical components are from famous foreign brands to ensure the stability of the system. The control system has a wide application. Each weigher signal collected by independent weighing Instrument, transferred by serial communications to specialize computer control board collecting external digital signals and realizes automatic production. High precision, strong antijamming capability. Besides customized services are approved.

Features At A Glance:

1.Full automatic control industrial computer, runs fast, strong anti-interference capability, efficient performance.

2 Functions such as automatically material supplement, smart fall correction improve weighing and batching precision greatly and guarantee excellent mixing quality.

3 Adopting man-machine conversation, each weighing meter response one weigher, industrial computer and weighing meter reads weighing value synchronously, which make it easy for whole process monitoring.

4 Control system software can provide analog display of whole production process, implementing a real time monitoring.

5 Imported microwave moisture probe can real-time detect concrete moisture and self-correcting. It can guarantee the concrete quality.

6 The control system integrated with self-locking and interlock function, fault alarm function and fault showing, in order to correct and debugging in time to make sure security and resume production.

7 Easy control of batches quantity. Input batch quantity and choose auto--operation mode to realize continuous production. ® Enhanced recipe editing and memory function. User can easily edit, save and select recipe accordingly.

9 Enhanced data memory and management function which realize unified management of material, ratio, order, trucks and personnel.

10 Enhanced report output and print function, which makes it easy to search, print, manage and save data generated during production process.

Optional items

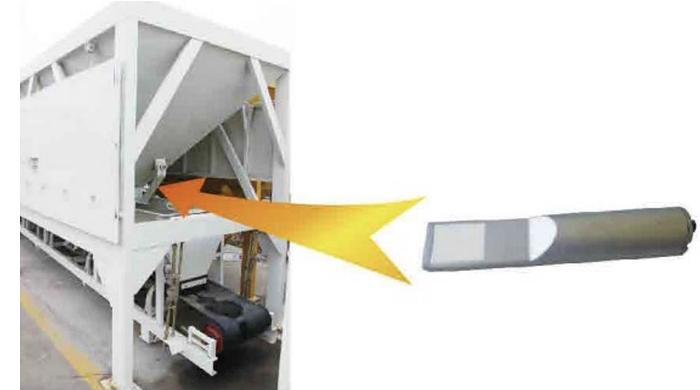

1 Skip hoist and weighing system. Planetary mixer equipped with skip hoist and weighing system. The inlet will open and close automatically when skip hoist lift to the inlet or descend (Patent), preventing dust from coming out of mixer as a result of Environmental controls. Cement scale and water scale (Include precision measurement) are designed very reasonably. Weighing is more accurate.

2.Environmentally Friendly Anti-Block Feeding Device. Specially designed environment-friendly anti-block feeding device(patented). The design of the outer slide rail prevents the Inlet gate from blocking and leads to better sealing.

The Security Device of Skip Hopper.

The security device of skip hopper safeguards against head injury when the hopper is travelling

upwards.

4 High Pressure Washing.

Automatic high pressure cleaning system washing with the use of a rotating high pressure

nozzle that only takes several minutes, cleaning the mixer walls, mixing tools and the entire

interior. This greatly improves the cleaning effect, reducing cleaning times and labour and

improves the working environment.

Temperature and Moisture Sensor

High precision and dynamical measuring supplies accurate value of temperature and moisture, which can achieve better performance of the mixture.

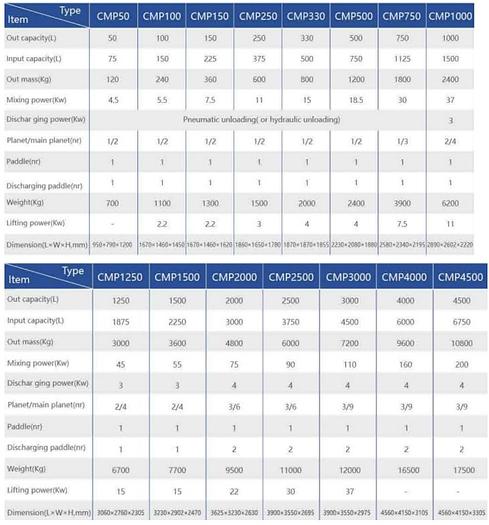

Specifications

| Manufacturer | Co-Nele |

| Condition | New |

| Stock Number | CMP PLANETARY MIXER |