As modern agriculture pursues efficiency and precision, compound fertilizer production technology is undergoing profound changes. As core equipment in fertilizer production, the new generation high-intensity mixed compound fertilizer granulator, with its outstanding innovative performance, is leading the industry towards higher yields and better quality.

Challenges of Traditional Granulation

Traditional compound fertilizer granulation methods often face numerous bottlenecks: limited production capacity, making it difficult to meet the needs of large-scale agriculture; low granule strength, which easily breaks and disintegrates during transportation and storage; and poor granule uniformity, which affects fertilization accuracy and efficiency.

Innovative Compound Fertilizer Granulator Technology Breaks Through Bottlenecks

The new generation high-intensity mixed compound fertilizer granulator successfully addresses these challenges through multiple technological innovations:

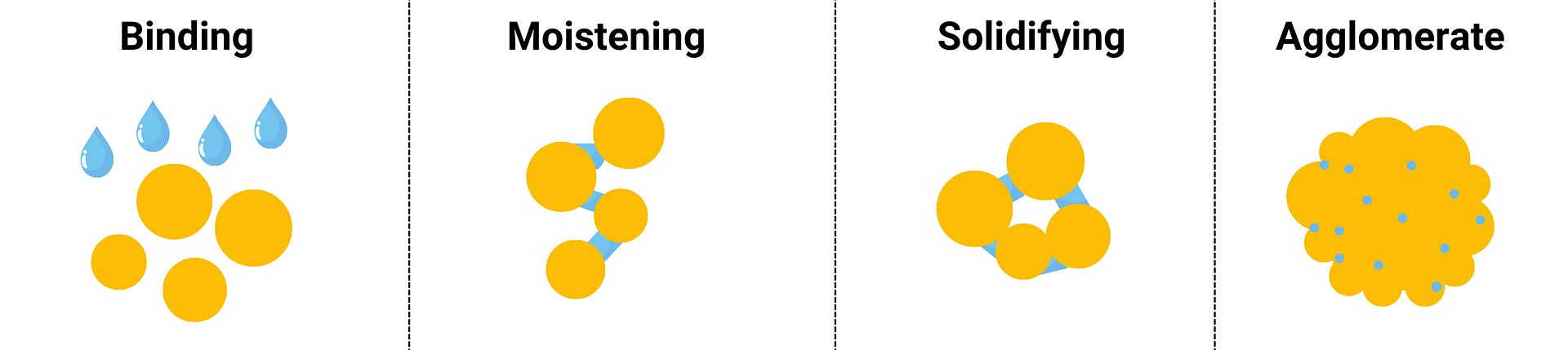

High-Intensity Dynamic Mixing: Utilizing a unique rotor structure and mixing design, the granulator achieves instant and thorough mixing and kneading of materials within the machine. This high-intensity force ensures uniform distribution of raw materials (such as nitrogen, phosphorus, potassium, and trace elements), laying a solid foundation for the production of high-quality granules with consistent composition.

A leap in production capacity: The new generation of compound fertilizer granulators can easily increase production capacity by 20%-30% or even more, meeting the needs of modern fertilizer companies for large-scale, continuous production.

Excellent quality: The compound fertilizer granules produced are beautifully spherical, uniform in size, high in strength, and resistant to clumping. This not only enhances the product's aesthetic appeal but also ensures uniform fertilizer release into the soil, improving nutrient utilization.

Energy efficiency and energy saving: Higher granulation rates and shorter granulation times mean lower energy consumption and raw material waste, bringing significant economic benefits to companies.

Wide adaptability: This equipment has a high tolerance for raw material compatibility and can adapt to the production of compound fertilizers and organic-inorganic blends with diverse formulations and process requirements, demonstrating tremendous flexibility.

This new generation of high-intensity mixed compound fertilizer granulators is more than just a production tool; it is a key engine driving the upgrading of the fertilizer industry and serving modern precision agriculture. Through its dual innovations in production capacity and product quality, it has injected strong momentum into the sustainable development of global agriculture, marking a new era of high efficiency and high quality in compound fertilizer production.