1. Project Background and Industry Challenges

In the R&D and small-scale production of metal powders, such as in 3D printing, metal injection molding (MIM), and cemented carbide preparation, efficiently and uniformly converting fine metal powders into granules of specific size, shape, and density is a core process challenge. Traditional mixing and granulation methods often suffer from low efficiency, poor uniformity, and insufficient granule density. Furthermore, achieving process repeatability and linear scalability in the laboratory is difficult, severely hindering the development speed of new materials and product quality.

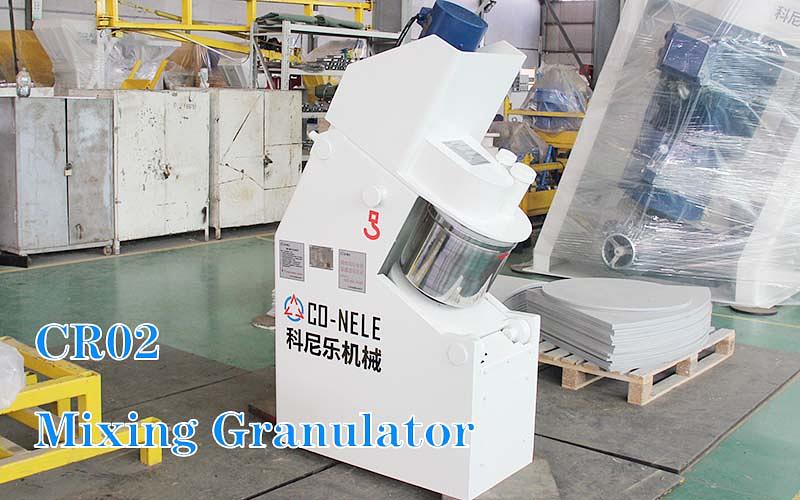

2. Solution: CO-NELE CR02 Laboratory Granulator

To address these challenges, the CR02 Laboratory Granulator from Qingdao Co-NELE Machinery Co., Ltd. (CO-NELE) provides an integrated, efficient solution. This device combines mixing and granulation functions. Its design, based on the principle of strong countercurrent mixing, is particularly suitable for processing demanding materials such as metal powders.

As a high-performance metal powder granulator, the CR02 can produce micron- and even nanometer-scale metal powders into uniform, dense spherical particles, laying a solid foundation for subsequent pressing, sintering, and other processes. Its 5L capacity is perfectly suited for both laboratory R&D and small-batch production.

CR02 laboratory metal powder granulator

CO-NELE laboratory metal powder granulator integrates mixing and granulation functions to quickly produce uniform and dense metal powder particles. It provides reliable equipment support for the research and development and scale-up of 3D printing, MIM and other processes.

3. Application Highlights and Value

3.1 Excellent Particle Quality

High Particle Formation Rate and Uniformity: The CR02 granulator produces metal powder particles of uniform size, regular shape, and high density. This ensures consistent flowability and filling properties in subsequent processes, resulting in more stable density and performance in the final product.

Precise Particle Size Control: The rotating mixing drum and granulation tool assembly of the device both support variable frequency control. By precisely adjusting the rotational speed, the operator can directly control the particle size, enabling online adjustment to meet the precise particle size requirements of different applications.

3.2 Efficient Process

Integrated Mixing and Granulation: The CR02 combines mixing and granulation within a single device, streamlining operations and reducing material transfer. This not only improves efficiency but also reduces the risk of cross-contamination and material loss.

High Speed and Efficiency: This device produces high-quality granules in a very short mixing and granulation time, significantly improving R&D efficiency.

3.3 Excellent Process Reproducibility and Scalability

Linear Scalability: The CR02's laboratory results can be reliably scaled to industrial-scale production. This feature is crucial for facilitating metal powder formulation development and mass production, significantly reducing risk and cost during the industrialization process.

3.4 Safety and Adaptability

Adaptability to Specialized Operating Conditions: The Lab Granulator is suitable for metal powders requiring explosion-proof properties and supports vacuum operation. This provides safe and reliable handling of reactive metal powders that are easily oxidized or sensitive to atmospheric conditions, such as titanium and aluminum powders.

4. CO-NELE Brand and Core Technology Advantages

Qingdao CO-NELE possesses extensive expertise in granulation and powder handling technology. Its core countercurrent relative motion principle combines the low-speed orbital rotation of the mixing drum with the internal high-speed rotation of the rotor, generating intense shear, convection, and diffusion effects within the material.

This inclined design ensures smooth, three-dimensional material movement, achieving satisfactory mixing and granulation results even when the drum is only half-filled. Furthermore, the smooth interior of the equipment, with no dead corners, allows for quick and clean discharge and easy cleaning, making it ideal for switching between metal powder experiments with different formulations.

5. Conclusion

The CO-NELE CR02 laboratory granulator, with its precise particle size control, excellent pellet quality, efficient integrated operation, and seamless scalability from laboratory to production, has become a trusted metal powder granulating mixer for metal powder R&D and small- and medium-scale production. It not only solves the key technical pain points in the metal powder granulation process, but also provides strong equipment support for the rapid development and quality consistency of new materials and new products through repeatable and controllable processes. It is an ideal tool for promoting the development of advanced metal materials.