Research Pain Points in Alumina Powder Granulation

In university materials science and engineering laboratories, alumina granulation is a key process for preparing high-performance ceramic precursors. Whether used for catalytic supports, structural ceramics, or electronic ceramics, the quality of alumina powder granulation directly determines the performance of the final product.

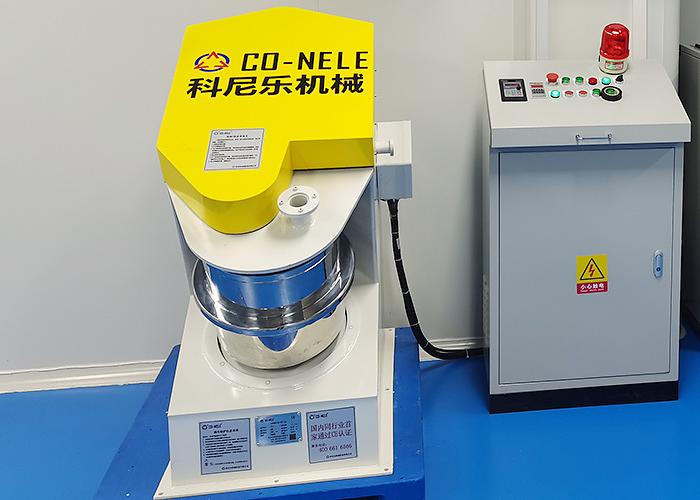

A university laboratory introduced the CO-NELE CEL5 laboratory-specific small alumina granulator, achieving a significant improvement in research and teaching efficiency.

Solution: The Core Value of a Professional Laboratory Small Granulator

The CEL5 alumina granulator, with its precision, efficiency, and transparency, has become a core laboratory equipment.

Key Parameters: The CEL5 laboratory granulator has a processing capacity of as little as 500-5000 ml, making it ideal for initial screening of alumina formulations and process exploration, minimizing material costs per experiment.

Core Process: The equipment utilizes three-dimensional turbulent flow granulation technology. The barrel and rotor utilize an inversely asymmetric design, generating strong countercurrent shear during operation. This ensures 100% efficient mixing of the material, resulting in the production of alumina particles with excellent sphericity and uniform density.

Key Parameter: The rotor speed typically ranges from 5 to 20,000 rpm and can be precisely adjusted to meet the full range of process requirements, from gentle mixing to aggressive granulation.